Greenhouse Coverings

How To Keep Your Greenhouse Cool

Greenhouses are designed to protect your plants and veggies from the elements, and that includes excessive heat. Gardening is a popular pastime, with one study showing that approximately 49% or nearly half of all Americans maintain some kind of garden. Whether you're a professional farmer or a casual gardener, read on for some greenhouse cooling tips. These tips will help keep your greenhouse at a comfortable temperature all summer long.

Read more

How to Install Landscape Fabric for Your Garden

Landscape fabric can keep weeds at bay, making maintaining your garden and greenhouse beds easier. Installing landscape fabric is a straightforward process, but you'll want to familiarize yourself with the steps. Read more

High Tunnel vs. Greenhouse - Pros and Cons of Each

Finding the right structure to grow your plants in requires knowing your options. When it comes to high tunnel vs. greenhouse, here are their pros and cons. Read more

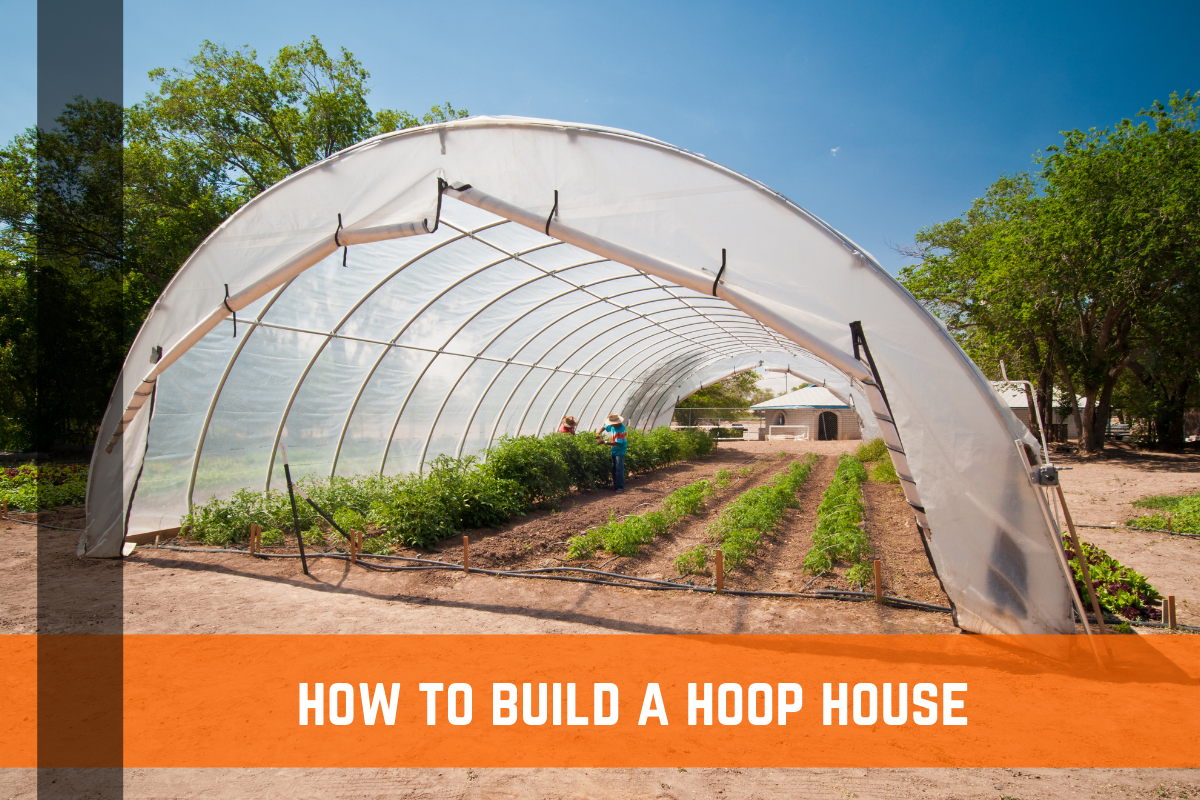

How to Build a Hoop House Greenhouse

If you’re looking to build something decently inexpensive that’s a great place to grow food in a smaller, vertical area, look no further than a DIY hoop house greenhouse. Read more

Does Landscape Fabric Work?

Landscape fabric is widely marketed as an easy way to control weeds and maintain a beautiful garden. But does it live up to the hype? In this article, we’ll explore the pros and cons of landscape fabric, how it functions, and whether it’s the right choice for your garden or yard. Read more

Showing 1 to 5 of 5 (1 Pages)